Liquid Crystal Sensors for Ultrasound

Ultrasonic testing plays a large part in NDT. To test a component, pulses of ultrasound are sent through the sample or along its surface, and any cracks or other defects will partially or fully reflect or block the waves. Scanning is often used to inspect the whole of the sample. This can give a very slow inspection process, which can cause delays where large scale testing and monitoring is necessary.

What if instead we could create a paint that can change from white to transparent under the influence of ultrasound or vibration? If the paint has a broadband response and is sensitive to different types of ultrasonic wave, it would be able to show visually the waves when they reach the sample surface. This would open up a wide variety of opportunities such as embedded sensors, smart coatings that help identify problems visually and at low cost. Important structural safety data could be collected by anyone with mobile phone with a camera, and sent to a monitoring centre, instead of having to train people in rather complex testing procedures. But how can one achieve this?

The answer may be by using liquid crystals. These materials are used in displays, such as for phones and computers. Liquid crystals are very sensitive to external fields such as voltage. They are also sensitive to displacement - try pushing a liquid crystal display with your finger! - which means that they are sensitive to ultrasound. While liquid crystal films require complex technological processes to be made into displays, there is a simple low-cost alternative. One can instead put small droplets of liquid crystal into a polymer matrix and make flexible large area films. When no field is applied, the liquid crystals in the droplets are not aligned, and the film is highly scattering to light, leading to a white appearance. When a field, such as an ultrasound wave, is incident on the film, the liquid crystals start to align, and the film becomes transparent. These films are sensitive to ultrasound and will go from opaque (white) to transparent when excited.

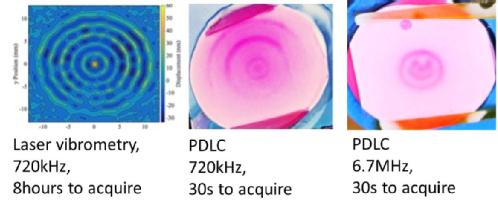

An initial prototype polymer dispersed liquid crystal sensor has been developed and used to visualised the vibrational modes of a flexural transducer. A constrasting paint layer was painted onto the transducer to help with contrast, then a 100 μm thick layer of the polymer dispersed liquid crystal was placed on top. A laser vibrometry scan of the mode at 720 kHz is shown below, which gives excellent resolution but took around 8 hours to produce. The central image shows the image obtained in just a few seconds (following around 30 s for the sensor to warm up) using the liquid crystal sensor. This means that it is now possible to test vibrational patterns of transducers over a very wide range of frequencies in less than 5 minutes, something unfeasible using other methods. The third image shows a resonance mode at 6.7 MHz, showing the broadband nature of the sensor (as well as the interesting shape of one of the higher-order resonance modes!).

The approach should work on many different types of materials, and isn't limited to metals. Once a component is coated, it could be tested every day if required, using a transducer operating at different frequencies to generate different wave modes. The ultimate aim is to develop this as a smart paint that can be applied to a component, structure, or even patient, that would visualise ultrasound or vibration with high sensitivity and resolution.

See a video of "painting" using sound waves here; https://www.youtube.com/watch?v=JF7dswTeB_A

Publications:

O. Trushkevych, T.J.R. Eriksson, S.N. Ramadas, S. Dixon and R.S. Edwards, “Acousto-optics with polymer dispersed liquid crystals for ultrasound sensing”, Applied Physics Letters 107, 054102, 2015