Materials

Our Laboratories

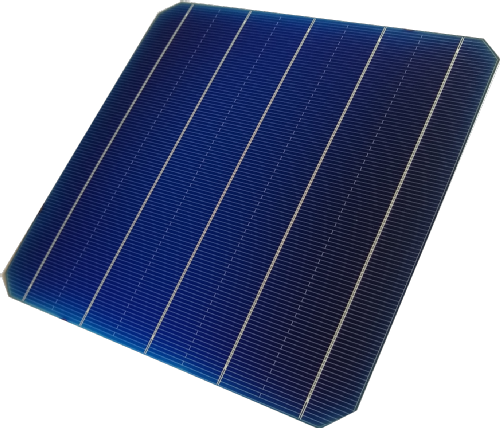

Electronic Materials and Interfaces Laboratory (John D. Murphy and Nicholas E. Grant)

The group's work is largely experimental and focusses on electronic materials for a range of applications including photovoltaics, batteries, optoelectronics, power electronics, and modulation of terahertz radiation. We are interested in the materials science of defects in the bulk of crystalline materials and in controlling the properties of surfaces as the nanoscale. Materials of current interest include silicon, germanium, silicon carbide, and 2D transition metal dichalcogenides (particularly MoS 2 ).

We maintain an atomic layer deposition (ALD) facility and are core users of the Science City Cleanroom in the School of Engineering. We also have our own characterisation laboratories. We have facilities for the measurement of minority carrier lifetime in silicon by quasi-steady-state photoconductance (QSS-PC), quasi-steady-state photoluminescence (QSS-PL), and photoluminescence imaging. We have a scanning Kelvin probe set-up, and also a system for performing cyclic tests on batteries. We have glovebox facilities for processing superacidic solutions and battery electrode materials. We are regular users of various Research Technology Platforms at Warwick, including Electron Microscopy, Spectroscopy, X-Ray Diffraction, and X-Ray Photoemission Spectroscopy.

We have led EPSRC projects in silicon photovoltaics and terahertz modulation, and we are part of the EPSRC Terabotics Programme Grant . We are part of the EPSRC SuperSolar Hub . We work on project to develop new technologies for solar cells, including the EPSRC COIL project . We have Leverhulme Trust Research Project Grant to determine the fundamental limit of silicon’s performance for solar cells. We have strong collaborations with leading groups worldwide, including at Oxford, Southampton, Exeter, Fraunhofer ISE, the Australian National University, and the University of New South Wales. We also work with some of the world’s largest solar cell manufacturers to develop higher efficiency and more stable commercial solar cell technologies. We are keen to hear from potential PhD students with backgrounds in Materials Science, Physics, Chemistry or Electronic/Electrical Engineering.

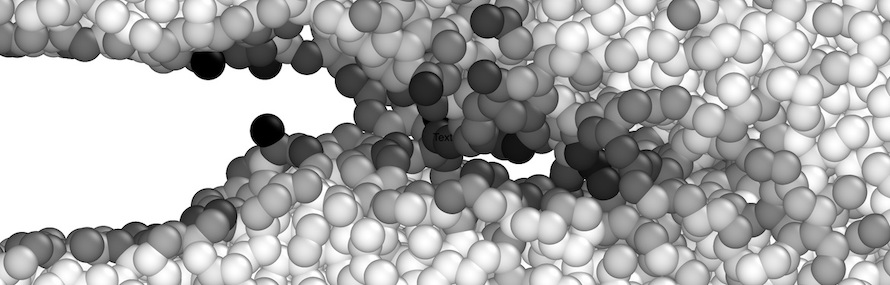

Multiscale Materials Modelling Laboratory (M3L; James Kermode, Peter Brommer, Albert Bartok-Partay and Michael Faulkner)

The group’s work is computational and theoretical in nature. We develop and apply methodology for modelling and simulating materials from the electronic structure scale through to atomistic and continuum scales. The group has a particular focus on bridging time and length scales using multiscale modelling techniques including both hierarchical and concurrent approaches to scale bridging.

Our expertise spans Condensed Matter Physics, Materials Science and Engineering and Computational Chemistry, and makes strong use of tools developed in the computational and mathematical sciences including machine learning, artificial intelligence and Bayesian inference – for example to develop and apply machine learning based interatomic potentials for use in molecular dynamics simulations.

We are closely affiliated to the Warwick Centre for Predictive Modelling and the EPSRC Centre for Doctoral Training in Modelling of Heterogenous Systems (HetSys) , and collaborate actively with theoretical and experimental colleagues across Warwick (e.g. in Physics, Chemistry, Mathematics and WMG) and beyond. We are users of the high-performance computing facilities run by the Scientific Computing Research Technology Platform (SCRTP).

| The Materials Group is part of the Mechanical, Materials and Process Stream |

Academic Staff