WMG News

Sustainable, low carbon circular plastic economy enabled by advanced plastic recycling process

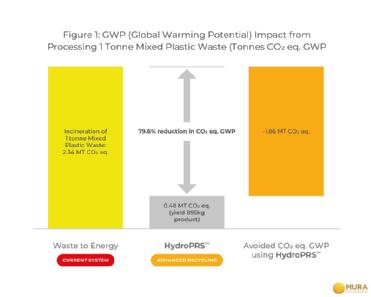

New research shows an 80% reduction in global warming potential (GWP), when compared to incineration, by processing waste plastic via a unique advanced recycling solution known as HydroPRS™, in a paper published by experts at WMG, University of Warwick.

solution known as HydroPRS™, in a paper published by experts at WMG, University of Warwick.

Researchers from WMG’s Sustainable Materials and Manufacturing team have been working with Mura Technology on a project focusing on the advanced recycling industry and the environmental impact of the associated processes.

Advanced recycling technologies (also known as chemical recycling) include a range of processes that break plastics down, converting them into hydrocarbon products that can replace the virgin fossil feedstocks used by the chemicals industry to create new plastics and other industrial products such as asphalt.

Dr Stuart Coles, Reader of Sustainable Materials and Manufacturing at WMG, University of Warwick, explained: “Advanced recycling will play an important role in realising the circular economy of plastics. The work conducted at WMG demonstrates a clear pathway towards Net Zero in recycled plastics and highlights improvements on the environmental footprint when compared with both existing production and disposal routes.

“We are delighted to see this work published as we explore the full potential of this technology moving forward.”

The peer-reviewed Life Cycle Assessment (LCA), reports that significantly reduced carbon emissions (measured as GWP in kilograms of CO2 equivalents) can be achieved if waste plastic is diverted towards HydroPRS™ and away from waste incineration – a comparable end of life treatment and currently, the fate of many ‘unrecyclable’ plastics.

Pioneered by Mura Technology, HydroPRS™, unlike pyrolysis, utilises supercritical water to convert post-consumer flexible, multi-layered and rigid plastics into high yields of stable, premium petrochemical feedstocks. Importantly, the products produced in the HydroPRS™ process were found in the LCA to have at least a comparable GWP when compared with naphtha, the fossil oil-based feedstock used in the production of plastics.

Dr Steve Mahon, Mura Technology’s CEO, said: “Resolving the global plastics crisis while reducing carbon emissions globally will inextricably require that the world is able to substitute fossil-based naphtha and other hydrocarbons for more sustainable feedstocks. This is Mura Technology’s ultimate goal and our innately scalable, innovative advanced recycling process using supercritical water is uniquely placed to pave the way to enable a low-carbon global circular plastics economy.”

Currently, the fate of unrecycled waste plastics is landfill, incineration or leakage into our waterways and oceans. All have negative impacts on the environment. Whilst incineration recovers some energy from plastic, none of these processes keep material within the circular economy, which in turn sustains the demand for virgin plastic from fossil-based sources.

Mura’s Chief Sustainability Officer, Dr Geoff Brighty, added: “As the global economy transitions away from fossil fuels, circular economies must operate at as low an environmental cost as possible. Alongside using the LCA to identify process improvements, the WMG team have demonstrated a clear, deliverable pathway to Net Zero for the HydroPRS™ process. This will help Mura decarbonise the petrochemical sector, whilst also reducing demand for fossil oil for plastic production by regenerating plastic waste into their feedstocks.”

The LCA is focussed on Mura’s first site in Teesside, UK and was funded through Innovate UK’s Smart Sustainable Plastic Packaging challenge (SSPP), as part of one of the demonstrator projects (grant number 49801).

Read the Hydrothermal Treatment of Waste Plastics: An Environmental Impact Study paper in full here s10924-023-02792-3.pdf (springer.com)

Coventry schools to build future cities from recycled household items

· TeenTech is a national charity working with school children to help them consider a future in digital, science technology and engineering.

· Their TeenTech City of Tomorrow initiative is working with nine Coventry schools with the help of WMG, University of Warwick

· Experts from WMG will deliver advice to children on sustainable materials, and inspire them as they design and build their city of the future out of recyclable household items

· A few Cities will then be exhibited at The Coventry Transport Museum

TeenTech City of Tomorrow will see Coventry school children make a city of recyclable household items, with help from researchers at WMG, University of Warwick who will teach them all about sustainability. A select few ideas – buildings and technology- will then be exhibited at the Coventry Transport Museum.

TeenTech is a national charity engaging children and teenagers in Digital, Science, Engineering and Technology and their latest initiative has launched today, the 11th November, in Coventry, which will see nine schools in Coventry build a futuristic sustainable city out of recyclable household items.

As it’s ‘Cities, Regions and Built Environment’ day at the COP26 summit in Glasgow, researchers from WMG at the University of Warwick are helping children understand sustainability and its importance, by delivering an online session about sustainable materials and why it’s important we use them more for a greener future, thanks to funding from the University’s Innovative Manufacturing and Future Materials GRP.

The children will then have two weeks to build their cities from recyclable household items. Three researchers from WMG, University of Warwick will run workshops, educating the children in using natural products for sustainable solutions and how to dispose of products.

On the 25th November the researchers from will then provide feedback, before selecting a few of the buildings and ideas to be exhibited at the Coventry Transport Museum from the end of the month.

Dr Stuart Coles from WMG, University of Warwick comments:

“Having spent my career researching how to reduce, reuse and recycle materials I am honoured to be a part of the TeenTech City of Tomorrow initiative, and look forward to seeing how creative the children can be in making a futuristic and environmentally friendly city.

“It is our children that will suffer from the damage we have caused and are causing to the planet, therefore it is imperative that we educate them from young age about sustainability and how they can create a cleaner and greener future for themselves and future generations, whilst we work out how we can change our ways to further prevent the climate crisis.”

Maggie Philbin, CEO of TeenTech comments:

“We want young people in Coventry to understand they can shape the future with their ideas. Young people think boldly, differently and inclusively and this is the thinking we need for a sustainable future. Tomorrow is very much a two-way event – experts will be sharing their knowledge, but we know that it will be the children who surprise everyone with their creativity, honesty and who will be the ones to challenge outdated thinking.

“Their buildings may be constructed from cardboard boxes but their ideas will be sophisticated and ones which should be seriously considered. They really are the architects, the engineers and the designers of the future. Let’s listen to them.”

Mrs Kaur, Class Teacher at Courthouse Green primary school comments:

"TeenTech is a great project to engage and enthuse the children and encourages them to consider how to be responsible about improving their environment. It has given the children the opportunity to think big about their world. their future and their role within it.

"The children are learning life skills, teamwork and are thinking outside the box to design and create cities that could effect change. The project is amazing! If I could give up a whole week to work on this, I would...it's real-life skills in the classroom."

Two children from year 5 at Courthouse Green Primary school have said:

"I love the project because it will help the future. It has made me think about climate change and how it is affecting our cities. In Coventry I see lots of litter and it gives our city a bad reputation. My team, Team Queen Tech are designing a treehouse from recycled materials that filters wastewater to use again." - Bhavika age 9

"We have designed a hotel for homeless people which is made from sustainable materials like bamboo." Sanjot Age 9

Electric vehicles could be powered by Hydrogen harvested from sewage

Hydrogen is valuable as it is a renewable source, and could be sold to the chemicals and plastics industry or used in hydrogen fuel cells for energy storage or electric vehicles

Hydrogen is valuable as it is a renewable source, and could be sold to the chemicals and plastics industry or used in hydrogen fuel cells for energy storage or electric vehicles- The ability to take hydrogen from waste water provides a new economic and environmental opportunity, however until now it has been incredibly expensive to suffice

- Using a recycled carbon fibre mat, researchers from WMG, University of Warwick, have been able to produce Hydrogen from wastewater for Severn Trent

Wastewater treatment is vital to remove pathogens, but is incredibly energy intensive. The ability to treat it more sustainably is a challenge researchers from WMG, University of Warwick have been able to achieve, using recycled carbon fibre mats to produce hydrogen from waste water.

Treating wastewater is a vital process, as it removes pathogens and protects the environment, however this comes at its own environmental cost, as it is highly energy intensive, using around 3% of energy use in the UK – the equivalent to 13 billion kilowatt hours.

The water and waste company Severn Trent set researchers from WMG, University of Warwick, the challenge of finding a more energy efficient way to treat wastewater, with the team successfully building on research into Microbial Electrolysis Cells.

Microbial Electrolysis Cells involves using electromagnetic microorganisms to break down organic pollutants in waste water, producing clean water and hydrogen gas. The ability to produce Hydrogen gas is valuable in itself as it can be sold to chemical and plastics industry, or for use in hydrogen fuel cells for energy storage or electric vehicles.

Although this all sounds promising it hasn’t been developed on an industrial scale, as the anode materials - which are used in the reaction to breakdown the organic pollutants – are made of graphite or carbon, and cost several hundred pounds per square metre, and produce low rates for Hydrogen.

Dr Stuart Coles and his team therefore took on the challenge of refining the technique by looking at alternative anode materials and processing methods, and successfully identified recycled carbon fibre mats as an alternative anode, which costs only £2 per square metre, making it significantly cheaper than existing anode materials.

After testing the carbon fibre mats on synthetic wastewater and real wastewater, researchers found the bacteria developed on the recycled carbon fibre anode, which had better temperature tolerance and produced more hydrogen than previously used materials.

They then decided to pilot their techniques at Severn Trent’s Minworth waste treatment site, where they successfully processed up to 100 litres of wastewater per day and managed to remove 51% of organic pollutants and up to 100% of suspended solids from the water while producing 18 times more hydrogen (at 100% purity) than the graphite material.

Dr Stuart Coles, from WMG, University of Warwick comments:

Dr Stuart Coles, from WMG, University of Warwick comments:

“We are really excited about this technology. By taking waste from the automotive and aerospace sectors, we have developed a circular solution to a longstanding problem. Instead of just treating the wastewater, we are now able to extract value from it in the form of hydrogen at a lower cost than ever before.

“The next phase of this work is look at optimising the design of the microbial electrolysis cells and further reduce the level of pollutants in the water. This in turn should help produce even more hydrogen!”

Bob Stear, Chief Engineer at Severn Trent adds:

“The performance boost and cost savings demonstrated from this research mean that MEC technology is one step closer to being cost competitive with existing wastewater treatment assets. WMG have also demonstrated that this technology has the potential to create a more circular wastewater treatment process which will be essential to delivering on our long term sustainability goals and Net Zero plans. We’re currently scoping scaling up the technology at our test-bed plant in Redditch.”

ENDS

2 NOVEMBER 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/img_1054.jpg

Caption: Dr Stuart Coles from WMG, University of Warwick with graphene

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/img_1054.jpg

Caption: Dr Stuart Coles from WMG, University of Warwick with graphene

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/img_1043.jpg

Caption: Dr Stuart Coles from WMG, University of Warwick with graphene

Credit: WMG, University of Warwick

https://warwick.ac.uk/services/communications/medialibrary/images/september_2021/img_1058.jpg

Caption: A sample of a roll of graphene

Credit: WMG, University of Warwick

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

WMG Professor joins Clean Growth Leadership Network

Head of WMG’s Sustainable Materials and Manufacturing Research Group, Professor Kerry Kirwan, has been appointed as a Fellow to the Clean Growth Leadership Network (CGLN).

Head of WMG’s Sustainable Materials and Manufacturing Research Group, Professor Kerry Kirwan, has been appointed as a Fellow to the Clean Growth Leadership Network (CGLN).

The CGLN is committed to economic growth for all whilst substantially reducing carbon emissions. The world-class network is made up of Founders, Fellows, Partners and Members united in their commitment to transform to a global clean economy.

Professor Kirwan explains: “I am delighted to have been appointed as a Fellow of the Clean Growth Leadership Network – the opportunity to work with some of the UK’s leading thinkers and practitioners tackling critical issues on the climate change agenda is hugely exciting. I’m really looking forward to introducing them to our research here at WMG and the wider University.”

Professor Kirwan is a specialist in circular economy, sustainable materials, polymer processing and industrial applications. He has extensive experience of developing environmentally friendly materials for application within numerous industries.

Read more about WMG’s Sustainable Materials and Manufacturing research here: Sustainable materials and manufacturing (warwick.ac.uk)

WMG Professors help tackle Net Zero solutions ahead of COP26

Ahead of COP26, voices across the political spectrum and from a range of leading UK universities have come together to produce a unique collection of essays focusing on Net Zero solutions.

Each is co-written by an academic and a Parliamentarian and sets out the areas where work is still needed on climate policy and demonstrates how readily to hand many policy and technical solutions are. It showcases the strength of UK science and research and the level of cross-party support for climate action.

Two WMG Professors have produced essays as part of the series. Professor David Greenwood together with Lilian Greenwood MP, has written ‘Driving the electric vehicle revolution’, and Professor Kerry Kirwan has, with Ben Lake MP, written ‘Overcoming barriers to the circular economy’.

Caroline Lucas MP, Chair of the APPG on Climate Change, explains: “The APPG on Climate Change was founded to coincide with the passing of the 2008 Climate Change Act – a vote that achieved almost unanimous support from across the political spectrum. As current Chair of the APPG on Climate Change, I see great value in striving to maintain and build upon this cross-party consensus where possible. We won’t all agree on the necessary course of action in each sector. And we may not even agree on the speed or scale with which it is necessary to reduce emissions. But we share a common conviction that the climate crisis is a challenge that can and must be surmounted. Deeper engagement between parliamentarians and the scientific community is a vital step in ensuring that we do. It is in that spirit that I fully endorse the work that has gone into producing this collection of essays.”

In his essay, co-authored with Lilian Greenwood MP, Professor David Greenwood, CEO of WMG High Value Manufacturing Catapult at the University of Warwick explains: “Whilst the coronavirus pandemic has resulted in devastating personal and economic impacts, it has also caused us to challenge some of our preconceptions. The public has experienced clean air as a result of reduced transport and industrial emissions. People have taken to their bikes in record numbers and with the trials of rental e-scooters there’s a real opportunity for them to replace car and public transport usage for short journeys - at least in good weather.

In his essay, co-authored with Lilian Greenwood MP, Professor David Greenwood, CEO of WMG High Value Manufacturing Catapult at the University of Warwick explains: “Whilst the coronavirus pandemic has resulted in devastating personal and economic impacts, it has also caused us to challenge some of our preconceptions. The public has experienced clean air as a result of reduced transport and industrial emissions. People have taken to their bikes in record numbers and with the trials of rental e-scooters there’s a real opportunity for them to replace car and public transport usage for short journeys - at least in good weather.

“These behavioural shifts, along with the persistent drivers of air quality and climate change reinforce the shift to EVs.”

Kerry Kirwan, WMG’s Professor of Sustainable Materials and Manufacturing explains: “Given the continued focus on how we use our limited planetary resources, the potential for green business models and practices to help our economic recovery post-pandemic and the imminence of COP26, it is great to see such a breadth of collected thinking coming together in this publication – it was a really valuable exercise that I am very pleased to have been part of”.

Kerry Kirwan, WMG’s Professor of Sustainable Materials and Manufacturing explains: “Given the continued focus on how we use our limited planetary resources, the potential for green business models and practices to help our economic recovery post-pandemic and the imminence of COP26, it is great to see such a breadth of collected thinking coming together in this publication – it was a really valuable exercise that I am very pleased to have been part of”.

Read the report and essays in full here: https://www.policyconnect.org.uk/research/net-zero-exchanges-connecting-policy-and-research-climate-action

About the APPCCG

The All-Party Parliamentary Climate Change Group runs events and activities in parliament with the purpose of advancing understanding of policy issues surrounding climate change and enabling cross-party discussion and action on climate policy.

This is not an official feed of the House of Commons or the House of Lords. It has not been approved by either House or its committees. All-Party Parliamentary Groups, forums and commissions are informal groups of Members of both Houses with a common interest in particular issues. The views expressed in the webpages are those of the groups.

About Policy Connect

Policy Connect is a membership-based, not-for-profit, cross-party think tank.

We bring together parliamentarians and government in collaboration with academia, business and civil society to inform, influence and improve UK public policy through debate, research and innovative thinking, so as to improve peoples’ lives.

We lead and manage an extensive network of parliamentary groups, research commissions, forums and campaigns. We are a London living wage and disability confident employer and a Member of Social Enterprise UK, and have been operating since 1995. Our work focuses on key policy areas including: health & accessibility; education & skills; industry, technology & innovation; and sustainability.

We shape policy in Westminster through meetings, events, research and impact work.

WMG research recognised at key industry awards

WMG Professor Ton Peijs’s paper entitled: “Turning low-cost recycled paper into high-value binder-free all-cellulose panel products” has been awarded the prestigious Green Materials Journal Prize by IEC Publishing, part of the Institute of Civil Engineers.

WMG Professor Ton Peijs’s paper entitled: “Turning low-cost recycled paper into high-value binder-free all-cellulose panel products” has been awarded the prestigious Green Materials Journal Prize by IEC Publishing, part of the Institute of Civil Engineers.

The IEC Awards recognise research of exceptional quality and benefit to the civil engineering, construction and materials science community.

Professor Peijs will be officially presented with the award at a ceremony in London in October.

Ton Peijs is a Professor of Polymer Engineering and Director of the National Polymer Processing Centre at WMG. His research focuses mainly on materials and processing innovations in polymers and composites. Ton has made notable contributions to areas such as hybrids, multifunctional materials, damage tolerance and durability, natural fibres and bio-based materials, polymer fibres and nanocomposites. He has also pioneered the development of sustainable composites, including the development of fully recyclable all-polymer composites.

Read Professor Peijs’s paper in full here: Turning low-cost recycled paper into high-value binder-free all-cellulose panel products | Green Materials (icevirtuallibrary.com)

Read more about WMG’s plastics research here: Plastics (warwick.ac.uk)

Chitin can be successfully extracted from Black Soldier Fly husks

- Chitin comes from the husks of Black Soldier Fly Larvae, which are waste products of black soldier fly farming

- Black soldier fly farming is commonly done in parts of Africa and South East Asia, as they are used as a source of protein for livestock, therefore, to be able to use the husks could create a new economic opportunity

- The extraction process gives comparable quality material to other feedstocks, and extracts 50% of the available chitin in the husks researchers from WMG, University of Warwick have found

Chitin is a naturally occurring polymer from the husks of Black Soldier Fly larvae, usually considered a waste product from the farming of the Black Soldier Fly larvae. However, researchers from WMG at the University of Warwick decided to see if they could extract chitin from the husks, creating a new economic opportunity.

Black Soldier Fly larvae. However, researchers from WMG at the University of Warwick decided to see if they could extract chitin from the husks, creating a new economic opportunity.

Chitin is a sustainable source of protein in countries in South East Asia and south parts of Africa. When extracted it can be characterised and used in the biomedical industry, for example to make antiseptics and anticancer treatments.

In the report, ‘Purification of chitin from Black Soldier Fly larvae husks’, researchers from WMG at the University of Warwick have successfully extracted chitin from the husks of Black Fly Soldiers.

The extraction route developed in this work obtains around 50% of the total available chitin, which is comparable to existing processes.

Dr Stuart Coles, from WMG at the University of Warwick comments:

“We have found a new way of extracting chitin from the husks of Black Soldier Flies, which are commonly farmed in parts of Africa and South East Asia as they can be used as a source of protein for livestock.

“Chitin can be used to make antiseptics and anticancer treatments, so to be able to extract it from the husks which are a by-product of the farming process means that there’s potential to be more sustainable by using what would usually go to waste.”

The extraction process that the researchers developed at WMG used cheap and readily available materials to reduce the cost whilst still producing a high-quality material.

Dr Stuart Coles explains:

“The process involved the use of mild, readily available and inexpensive chemicals to breakdown the natural structure of the husk and allowed us to isolate the chitin. In isolating the chitin, we only used water as a solvent, and a large part of our work focused on reducing the amount of water being used as it is a critical resource in countries where Black Soldier Flies are farmed.”

Research can now continue to investigate how to commercialise the extraction process into a larger process.

ENDS

27 APRIL 2021

NOTES TO EDITORS

High-res images available at:

https://warwick.ac.uk/services/communications/medialibrary/images/april_2021/fly-1627592_1920.jpg

Caption: A Black Soldier Fly

Credit: Brett Hondow, Pixabay

For further information please contact:

Alice Scott

Media Relations Manager – Science

University of Warwick

Tel: +44 (0) 7920 531 221

E-mail: alice.j.scott@warwick.ac.uk

UK plastic recycling company receives £4.42m Government funding from Innovate UK for ground-breaking advanced recycling plant in the North East England

Advanced recycling company ReNew ELP, based in Teesside, has been awarded a £4.42 million grant from Innovate UK, the UK’s innovation agency, to build the world’s first commercial-scale plastic recycling plant using Cat-HTR™ technology. Focussing on the UK Government’s priority to drive economic growth through new technology, the award comes through the Industrial Strategy Challenge Fund’s Smart Sustainable Plastic Packaging programme. It recognises the commercial-scale feasibility of the technology and potential of the advanced recycling sector to help meet ambitious plastic recycling targets. The grant will aid ReNew ELP in the construction of the initial plant, which commences build in Q1 2021 and will see c. 80,000 tonnes of waste plastic recycled annually upon completion.

The technology, Cat-HTR™ (Catalytic Hydrothermal Reactor), uses supercritical water, heat and pressure to convert waste plastic considered ‘unrecyclable’ through traditional mechanical means back into the valuable chemicals and oils from which it was made, for use in the petrochemical industry in the production of new plastic and other materials. This helps to create a circular economy for waste plastic.

Rebecca Pow MP, Under-Secretary of State for Defra says: “The Government is committed to both clamping down on the unacceptable plastic waste that harms our environment and ensuring more materials can be reused instead of being thrown away. By investing in these truly ground-breaking technologies we will help to drive these efforts even further, and I look forward to seeing them develop and deliver real results.”

A key benefit of the Cat-HTR™ technology is its ability to recycle multi-layer, flexible plastic materials such as films, and pots, tubs and trays (PTT), considered unrecyclable through traditional mechanical recycling, and are instead sent to landfill or incineration. Vitally, new materials made from ReNew ELP’s advanced recycling feedstock are suitable for use in food-contact packaging material, a problem area for mechanical recycling systems whose products do not meet European Food Standard Agency requirements.

In line with the Government’s policy of ‘Producer Pays’, Cat-HTR™ offers a solution to producers, retailers and brand owners levied with the expected Plastic Packaging Tax, which enforces a 30% recycled content requirement for all plastic packaging in both the UK and pre-filled from overseas from 2022, alongside

Extended Producer Responsibility (EPR), which challenges those in the plastic value chain to pay the full net cost of waste material collection and recycling. Advanced recycling company ReNew ELP offers a beneficial technology to help increase the recycled content of packaging and provide a recycling solution for plastic packaging materials such as flexible films, pots, tubs and trays.

Alongside diverting plastic away from polluting the environment, the Cat-HTR™ technology represents significant overall environmental benefit. Initial independent studies have already shown that advanced recycling can reduce CO2 emissions by 1.5 tonnes for every tonne of plastic waste processed when compared to incineration. This means that the completed ReNew ELP site at Wilton will save approximately 120,000 tonnes of CO2 annually, when compared to incineration. Environmental benefits include:

· Reducing plastic pollution of the natural environment

· 1.5 tonnes CO2 emissions saving per tonne of plastic processed via advanced recycling when compared to incineration

· An increased scope of recyclable plastics, including those classed as ‘unrecyclable’

· As Cat-HTR™ is not a combustion process, it does not produce toxic by-products such as dioxins

· A reduction on fossil sourced feedstock for the manufacture of new plastics

· High yields - up to 85% of the mass of plastic is converted to hydrocarbon products

· Minimal waste is produced- impurities (colourants, additives, fillers etc.) in the plastic feedstock fall out into the heavier hydrocarbon feedstocks, which can be used in construction

WMG at the University of Warwick partner on the project, conducting detailed Life Cycle Assessments (LCAs) to quantify the benefits of advanced recycling across multiple environmental indicators.

Dr Stuart Coles, Associate Professor of Sustainable Materials who is leading the project in WMG at the University of Warwick says, “WMG will also be investigating what materials can be manufactured from the

Dr Stuart Coles, Associate Professor of Sustainable Materials who is leading the project in WMG at the University of Warwick says, “WMG will also be investigating what materials can be manufactured from the

Cat-HTR™ output streams. We will be able to link previously difficult to dispose of plastic materials to added-value products and demonstrate their potential through our characterisation and testing facilities.”

The technology demonstrates a complementary solution to sit alongside traditional mechanical recycling to create a circular economy. It also offers those in the plastic supply chain an alternative means for disposing of their flexible and multi-layer plastic packaging, which no longer needs to be incinerated or sent to landfill but can instead be recycled. This new process goes hand in hand with efforts to reduce single-use plastic and helps to create a plastic-neutral society.

ReNew ELP Managing Director Richard Daley says: “This Grant demonstrates we are in line with Government Policy and its drive towards achieving increased recycling targets in the UK. It will increase investor confidence, help innovative technologies such as ours break through and establish the Advanced Recycling Industry in the UK, helping ReNew ELP to emerge as a global leader in plastic recycling.”

WMG Professor takes on new role as Deputy PVC (Research) for Knowledge Exchange and Partnerships

Professor Kerry Kirwan has been appointed as the new Deputy Pro-Vice Chancellor (Research) for Knowledge Exchange and Partnerships, for the University of Warwick.

Knowledge exchange, industry partnerships and innovation are key components of much of the University’s research, with Professor Kirwan appointed to support this growing area.

Kerry, a Professor at WMG is also a Director of the £11m EPSRC Centre for Doctoral Training in Sustainable Materials and Manufacturing (EngD), Strategic Director of the £10m Industrial Doctorate Centre and Head of WMG’s Sustainable Materials and Manufacturing Research Group. He also sits on the University’s Research Executive Group.

Professor Kirwan is actively involved in the newly emerging Knowledge Exchange Framework programme, Monash-Warwick Alliance, Warwick in Europe, the Global Challenges Research Fund, Midlands Innovation, Energy Research Accelerator (ERA) and the Innovative Manufacturing and Future Materials GRP.

Speaking about his new appointment, Professor Kirwan said: “I am delighted to take up this position and very much look forward to continuing to work with the Pro-Vice Chancellor for Research to ensure we continue to grow our knowledge exchange, innovation and business and industry partnerships, and ultimately advance the outstanding research achievements of the University.”

Speaking about his new appointment, Professor Kirwan said: “I am delighted to take up this position and very much look forward to continuing to work with the Pro-Vice Chancellor for Research to ensure we continue to grow our knowledge exchange, innovation and business and industry partnerships, and ultimately advance the outstanding research achievements of the University.”

Professor Pam Thomas, Pro-Vice Chancellor (Research), commented: “Professor Kirwan will play a critical role and his skills and experience will be instrumental in furthering the development of Warwick as a leading research-intensive University with strong industry partnerships – locally, nationally and globally.”

Construction greener and more efficient with intelligent software

Construction vehicles could become more efficient and environmentally-friendly, thanks to new technology developed by WMG at the University of Warwick.

Through a new Innovate UK research programme, WMG in collaboration with partners JCB and Pektron PLC are working to optimise the fuel economy of the next generation of off-highway vehicles.

Dr James Marco from WMG is leading the University’s contribution to the project that aims to introduce new intelligent power systems for improved engine operation.

Dr James Marco from WMG is leading the University’s contribution to the project that aims to introduce new intelligent power systems for improved engine operation.

This could lead to significant fuel savings and fewer carbon emissions for the industry.

Dr Marco’s team is analysing JCB’s current fleet to better understand the opportunities for emissions reduction and intelligent control.

Today’s construction industry is more environmentally-conscious than ever, and the amount of CO2 emissions released by vehicles is a significant factor in deciding which ones to use during an assignment.