Engineers pave the way towards 3D printing of personal electronics

Scientists are developing new materials which could one day allow people to print out custom-designed personal electronics such as games controllers which perfectly fit their hand shape.

Scientists are developing new materials which could one day allow people to print out custom-designed personal electronics such as games controllers which perfectly fit their hand shape.

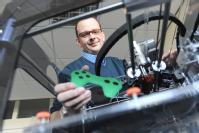

The University of Warwick researchers have created a simple and inexpensive conductive plastic composite that can be used to produce electronic devices using the latest generation of low-cost 3D printers designed for use by hobbyists and even in the home.

The material, nicknamed ‘carbomorph’, enables users to lay down electronic tracks and sensors as part of a 3D printed structure – allowing the printer to create touch-sensitive areas for example, which can then be connected to a simple electronic circuit board.

So far the team has used the material to print objects with embedded flex sensors or with touch-sensitive buttons such as computer game controllers or a mug which can tell how full it is.

The next step is to work on printing much more complex structures and electronic components including the wires and cables required to connect the devices to computers.

The research was led by Dr Simon Leigh in the School of Engineering at the University of Warwick.

Dr Leigh said: “It’s always great seeing the complex and intricate models of devices such as mobile phones or television remote controls that can be produced with 3D printing, but that’s it, they are invariably models that don’t really function.

“We set about trying to find a way in which we could actually print out a functioning electronic device from a 3D printer.

“In the long term, this technology could revolutionalise the way we produce the world around us, making products such as personal electronics a lot more individualised and unique and in the process reducing electronic waste.

“Designers could also use it to understand better how people tactilely interact with products by monitoring sensors embedded into objects.

“However, in the short term I can see this technology having a major impact in the educational sector for example, allowing the next generation of young engineers to get hands-on experience of using advanced manufacturing technology to design fairly high-tech devices and products right there in the classroom.”

The printed sensors can be monitored using existing open-source electronics and freely available programming libraries.

A major advantage of using 3D printing is that sockets for connection to equipment such as interface electronics can be printed out instead of connected using conductive glues or paints.

This research is detailed in the study, A simple, low-cost conductive composite material for 3D printing of electronic sensors, published in the open-access journal PLOS ONE.

The research was funded by the EPSRC project: Novel 3D Printing Technologies for Maximising Industrial Impact (Subproject # 30821) and by the EPSRC UK Research Centre In Nondestructive Evaluation.

ENDS

Further Information

Contacts

Simon Leigh is available on +44 (0)24 761 51357 or S.J.Leigh@warwick.ac.uk

Or you can contact University of Warwick press officer Anna Blackaby on a.blackaby@warwick.ac.uk or +44(0)2476 575910 or +44 (0)7785 433155

The open-access paper is available here

Facilities for broadcast media

We have an ISDN line and a Globelynx TVReady Network camera installed in our Broadcast Studio on campus for interviews with our academics.

ISDN - The number for the ISDN line is 02476 471287. To book time in the Broadcast Studio on campus, please call 02476 524668 or 02476 575601.

Globelynx TVReady - To connect with our camera you need to book a slot through the Globelynx website:

- Visit the Globelynx site and register or log-in.

- On the Globelynx site you can view some of our listed experts and areas of expertise. If the academic you wish to interview is listed there on the drop-down menu, select them and then follow the online booking procedure.

- If you would like to set up an interview with an academic who is not listed on the Globelynx database, please select 'The Studio at the University of Warwick' option from the drop-down menu and follow the online booking procedure. If you need assistance, please call Globelynx on +44 (0)20 7963 7061.

- If you have any problems, please call 02476 575601 or 02476 150868. Alternatively you can contact any member of our press team for assistance.

Crucial pieces of equipment used in this research were funded through the Science City Research Alliance (SCRA) Advanced Materials project. SCRA is a strategic research partnership between the University of Warwick and the University of Birmingham with a specific remit to work with businesses across the region. It has benefited from a multi-million pound investment in equipment and research infrastructure across both institutions via Birmingham Science City and the European Regional Development Fund.

Further Information

Contacts

Simon Leigh is available on +44 (0)24 761 51357 or S dot J dot Leigh at warwick dot ac dot uk

Or you can contact University of Warwick press officer Anna Blackaby on a dot blackaby at warwick dot ac dot ukor +44(0)2476 575910 or +44 (0)7785 433155

Related Links

The open-access paper is available here